A Rainbow of Safety: Understanding the Professional Color-Coding System for Cutting Boards

The humble cutting board is a kitchen essential, a silent workhorse in both the home and professional culinary environment. Yet, in many commercial kitchens and within the rigorous standards of food safety, the cutting board takes on a sophisticated role, often appearing in a variety of vibrant colors. This isn’t a matter of interior design or aesthetic choice; it’s a vital, internationally recognized system designed to prevent cross-contamination, a leading cause of foodborne illness.

Cross-contamination occurs when bacteria, viruses, or other harmful microorganisms are transferred from one food item (often raw) to another (often cooked or ready-to-eat), either directly or indirectly via surfaces, equipment, or hands. The consequences can range from mild discomfort to severe illness, making its prevention the cornerstone of responsible food handling. The professional color-coded cutting board system is an elegant, immediate, and effective solution to this critical problem.

This comprehensive guide will delve into the specific roles of each color, the science behind the system, its benefits, and how both professional chefs and home cooks can integrate this life-saving practice into their routines.

The Six Pillars of the Color-Coded System

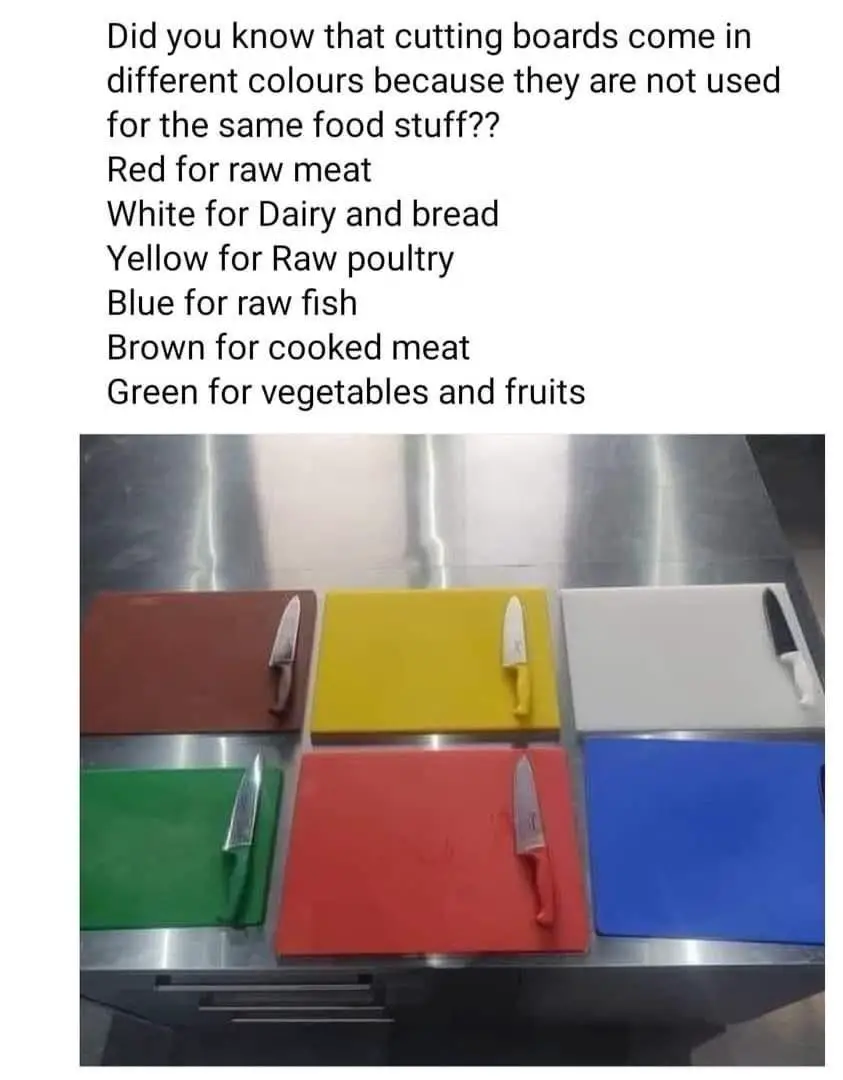

The system commonly used in commercial settings involves six distinct colors, each assigned to a specific food group. This allocation ensures that the board used for a highly hazardous raw food, such as chicken, is never mistakenly used for a ready-to-eat food, like bread or salad greens, without a thorough, potentially complex, sanitation process in between.

- Red: The Code for Raw Meat 🥩

The red cutting board is unequivocally designated for raw red meat, including beef, lamb, and pork.

Raw red meat is a significant source of pathogens, notably E. coli and Salmonella. By isolating all raw red meat preparation to the red board, kitchens create a dedicated zone for this high-risk food. This practice is particularly crucial because red meat juices can harbor these bacteria, and if those juices were to touch a surface intended for vegetables (which might be served raw), the risk of immediate illness is high. The visual cue of red is both a warning and a clear identifier, signaling the highest level of caution and the need for immediate, rigorous cleaning after use. - Yellow: The Poultry Perimeter 🐔

The yellow cutting board is reserved exclusively for raw poultry, which includes chicken, turkey, and duck.

Poultry is notoriously associated with Salmonella and Campylobacter, two of the most common causes of food poisoning worldwide. Because raw poultry requires cooking to a specific, high internal temperature to kill these bacteria, its juices are considered highly dangerous. The use of a yellow board provides a clear visual separation from other raw meats (red) and all other food groups, ensuring that the preparation space for raw chicken, for example, is entirely distinct from where a final garnish might be prepared. - Blue: The Aquatic Zone 🐟

The blue cutting board is dedicated to raw fish and seafood.

While often considered less hazardous than poultry, raw fish carries its own specific risks, including various bacteria, parasites (like Anisakis), and potential allergens. Using the blue board prevents the transfer of fish-related pathogens, scales, and strong odors or flavors to other foods. Furthermore, in an industry where allergens are a critical concern, keeping fish preparation separate helps manage the risk of cross-contact with major allergens like fin fish and shellfish. - Green: The Garden Standard 🥦

The green cutting board is meant for fresh produce, specifically vegetables, fruits, and salads.

This board is perhaps the most critical for preventing reverse cross-contamination. While raw meat introduces pathogens, the green board handles foods that are often served raw and ready-to-eat. If this board were to come into contact with residual Salmonella from a poultry board, the bacteria would go directly into the prepared salad without any heat treatment to kill them. The green board is a ‘safe zone’ for items that will not undergo a cooking step. - White: The Versatile Neutral 🍞

The white cutting board is typically designated for dairy and bread products.

In a professional kitchen, this often means cheese, butter, or for slicing baked goods. Because these items are generally ready-to-eat and low-risk from a primary pathogen standpoint (in comparison to raw meat), the white board acts as a neutral, general-purpose surface for foods that don’t fit into the high-hazard or fresh produce categories. It requires scrupulous cleanliness, as it is still an ‘end-of-line’ board for ready-to-eat consumption. Some systems also use white for general-purpose tasks where a dedicated board color isn’t necessary, but its role as the ‘cleanest’ and most neutral surface is paramount. - Brown: The Cooked Corridor 🥩

The brown cutting board is reserved for cooked meats and cooked food items.

Once a steak, roast, or piece of chicken has been safely cooked to its minimum internal temperature, it must be carved or sliced on a different surface than the one where it was raw. The brown board ensures that the now-safe cooked meat does not touch the same surface (and thus, the same pathogens) as its raw state. This is an essential final step in preventing cross-contamination, often referred to as ‘post-cook’ contamination.

The Science of Separation: Why Color Works

The effectiveness of this system lies in its simple, human-centric design. - Visual Cues and Cognitive Ease

Humans are highly visual creatures. The immediate, high-contrast nature of the color coding system makes it impossible to ignore. In a fast-paced, high-stress commercial kitchen environment—where time is short and mistakes are costly—a chef or line cook doesn’t have to stop and read a label or remember a rule. They see the food (e.g., raw fish) and immediately reach for the corresponding color (blue). This reduces cognitive load and minimizes the chance of human error, which is the weakest link in any food safety chain. - Standardization Across Cultures

The system is largely standardized globally, meaning a chef trained in London can instantly understand the food safety protocol in a kitchen in New York or Tokyo. This universal language of safety enhances mobility and professionalism within the culinary industry. - Accountability and Auditing

For health inspectors and kitchen managers, the system provides a clear, auditable check. A quick glance at the line setup can reveal if a cook is using the wrong board. If a red board is found near the salad station, it’s an immediate, actionable sign of a potential safety breach. This inherent structure enforces accountability among kitchen staff.

Beyond the Boards: A Holistic Approach to Food Safety

While the cutting boards are the centerpiece, the philosophy of color-coding often extends to other tools to maximize protection. - Color-Coded Knives and Utensils

In many professional settings, knives, tongs, scoops, and even sink brushes are also color-coded to match the boards. For instance, a red-handled knife is only used on the red board for raw meat. This prevents a secondary route of cross-contamination where a knife, used to cut raw chicken, might then be used to slice a cooked item, even if the cook used the correct board. This level of dedication creates a completely separate ‘raw’ workflow and ‘cooked/ready-to-eat’ workflow. - Storage and Sanitation

The color system also dictates storage and cleaning protocols. All raw-food boards (red, yellow, blue) should ideally be stored separately from ready-to-eat boards (green, white, brown). Furthermore, after cleaning, they should be sterilized—often in a commercial dishwasher that reaches temperatures high enough to kill spores and bacteria—and air-dried. The visual nature helps ensure that a cook isn’t stacking a clean green board directly on top of a used red board waiting to be washed. - The HACCP Connection

The color-coded system is a practical implementation of HACCP (Hazard Analysis Critical Control Point) principles. In HACCP, one of the primary goals is to identify Critical Control Points (CCPs) where a biological, chemical, or physical hazard can be prevented, eliminated, or reduced to an acceptable level. Cutting boards are a classic CCP. The color-coding is the preventive measure (or control) put in place to manage the hazard of cross-contamination.

Practical Application for the Home Cook

While the space and budget constraints of a home kitchen may not allow for six distinct professional boards, the core principle of the color-coded system remains invaluable. Home cooks can adapt this concept for a safer kitchen: - The Two-Board Rule

The absolute minimum safety requirement is two dedicated cutting boards. One must be reserved only for raw proteins (meat, poultry, and fish). The second must be reserved only for ready-to-eat foods (vegetables, fruits, bread, and cooked items). To enforce this, a home cook could simply purchase a red board for raw proteins and a green board for everything else, using the professional color-coding for clarity. - Material Matters

While the professional system often uses high-density polyethylene (HDPE) plastic boards (which are non-porous, dishwasher-safe, and durable), home cooks can use wood or plastic. If using wood, ensure it’s a hard wood (like maple) and that it’s meticulously cleaned, as wood can be more porous and harbor bacteria if not maintained correctly. However, a significant advantage of wood is that its inherent structure can draw bacteria away from the surface, essentially trapping it inside and away from food, but this is only true if the surface is kept dry. Plastic remains the safest, easiest-to-clean choice, especially since it can handle a dishwasher’s high-heat sanitizing cycle. - The “Wash, Rinse, Sanitize” Mantra

Regardless of the board’s color or material, the sequence is critical:

- Wash: Use hot, soapy water to remove all visible food particles.

- Rinse: Rinse off the soap residue.

- Sanitize (Home Method): Apply a mild bleach solution (1 tablespoon of bleach per gallon of water) or a commercial food-grade sanitizer, or simply run the board through the high-heat cycle of a dishwasher.

Common Misconceptions and Troubleshooting

Myth: Hot Water Alone Sanitizes

Reality: Hot water and soap remove grease and food residue, but they don’t necessarily kill pathogens. The board must be sanitized using heat (dishwasher) or a chemical solution (bleach/sanitizer) to be truly safe.

Myth: Just Rinse it Off

Reality: Rinsing a board used for raw meat and then cutting vegetables on it is a textbook case of cross-contamination. The rinsing process simply spreads the pathogens across the surface; it doesn’t eliminate them.

Troubleshooting: Scratches and Grooves

Over time, plastic cutting boards develop deep knife grooves. These grooves are a major hazard because bacteria can hide inside them, shielded from the cleaning process. A board with excessive gouges should be either resurfaced (by sanding or planing) or, more practically, replaced. The integrity of the smooth, non-porous surface is paramount to the system’s success.

Troubleshooting: Allergens

While the core system focuses on pathogens, the color-coding is also useful for allergen control. A kitchen may choose to use an additional, unassigned color (e.g., Purple) specifically for allergen-free preparation, ensuring no trace of common allergens like nuts, gluten, or soy comes into contact with the food being prepared for a sensitive customer.

The Global Impact of the System

The development and adoption of the color-coded cutting board system reflect a broader movement toward standardized food safety practices across the world. Driven by organizations like the World Health Organization (WHO) and national food safety bodies (such as the FDA in the US, the FSA in the UK, and EFSA in Europe), these protocols transform chaotic kitchen environments into structured, predictable systems.

In essence, the system elevates the cutting board from a simple tool to a critical safety barrier. It’s a perpetual, visible reminder of the high stakes involved in food preparation. By consistently adhering to this simple code of colors—red for danger, green for safety, and the others for clear categorization—kitchens maintain an environment where the ultimate goal is not just delicious food, but food that is, above all, safe to eat.

The colors on the board are not just colors; they are a language of life-saving hygiene, a testament to the dedication of the culinary industry to protect the public health. Understanding and implementing this vibrant rainbow of safety is the hallmark of any truly professional and responsible kitchen.